Hand soap

A private label hand soap from a local supermarket includes the following ingredients:

Aqua

Sodium laureth sulfate

Sodium chloride

Glycerin

Cocamidopropyl betaine

Tetrasodium glutamate diacetate

Propylene glycol

Benzotriazolyl dodecyl p-cresol

Parfum

Citral

Linalool

Limonene

Sodium benzoate

Citric acid

Sodium hydroxide

CI 19140

CI 42090

Key Ingredients and Their Functions

The main active ingredients in this private label hand soap are sodium laureth sulfate (SLES) and cocamidopropyl betaine (CAPB). Tetrasodium glutamate diacetate (GLDA) is a biodegradable chelating agent that helps improve product stability. Glycerin and propylene glycol serve as moisturizers. Apart from these, there are no particularly notable ingredients.

Benzotriazolyl dodecyl p-cresol is most likely included as an antioxidant to protect the fragrance components, which are the most susceptible to oxidative degradation. This could be useful if the product is intended to sit on a shelf for a year or more. However, this ingredient is not easy to source, so it is better to leave it out or use an alternative.

Allergens such as citral, linalool, and limonene must be listed on the label, although the perfume contains more components than just these three. Coloring agents, identified by “CI” followed by numbers, do not contribute any meaningful function and can be omitted.

How to Make a Simple Replica

You can either combine SLES and CAPB yourself or use a ready-made blend that also includes lauryl glucoside.

To prepare 1000 grams of basic hand soap, you will need the following ingredients

(quantities can be scaled as needed):

-

145 g of a surfactant blend containing SLES, CAPB, and lauryl glucoside

-

30 to 40 g of sodium chloride (regular table salt works well)

-

Citric acid solution for pH adjustment

-

Preservative

-

Water to make up to 1000 g

Procedure

-

Dissolve the surfactant blend in water.

-

Adjust the pH to approximately 5-5.5 using a citric acid solution.

-

Gradually add sodium chloride in small portions, about 2 grams at a time. Stir well between additions. Stop once the desired viscosity is reached.

-

Check the foaming performance. If the foam is excessive, dilute the formulation with water.

-

Add optional components, if desired. Common additives include:

-

Coco-glucoside/glyceryl oleate blend

-

Glycerin

-

Propylene glycol

-

Sodium lactate

-

Panthenol

-

-

Add the preservative. A combination of sodium benzoate and potassium sorbate is commonly used.

-

Transfer the finished product into a suitable container.

Notes

It is easier to adjust the pH before adding salt. Once the mixture thickens, adjusting pH becomes more difficult due to increased viscosity.

Use fragrance oil(s) of your choice instead of perfume.

The takeaway

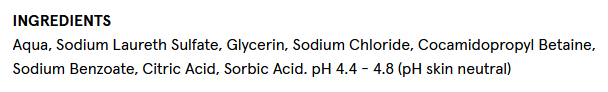

Still not convinced that the basic recipe will work? Let’s examine the composition of a hand soap that is proudly marketed as containing 0% perfume, 0% dyes, and 0% parabens.

Looking at the ingredient list, I don’t see anything that differs significantly from the basic formula. Do you? The inclusion of lauryl glucoside, a mild surfactant, simply helps improve foaming performance.

And the best part? It’s selling online for over €4 per 250 mL, which proves that even a simple formula can command a premium.

There are many possible approaches to formulating a liquid hand soap. For example, CAPB can be replaced with lauryl hydroxysultaine on a 1:1 active basis. A 40% CAPB solution is very similar to lauryl hydroxysultaine in terms of active content, while lauryl hydroxysultaine is considered milder and provides better foaming and thickening performance than cocamidopropyl betaine.

If you prefer a sulfate-free formulation, sodium laureth-5 carboxylate and coco betaine can be used in a 10:1 ratio based on active content. Keep the total level of active surfactants at approximately 7–9%, depending on the desired foam intensity. Add the desired thickener(s) and functional additives, then adjust the pH and incorporate preservatives. Sodium benzoate and potassium sorbate are often sufficient at a pH of 5.